The manufacturing process of metal buttons

The manufacturing process of metal buttons

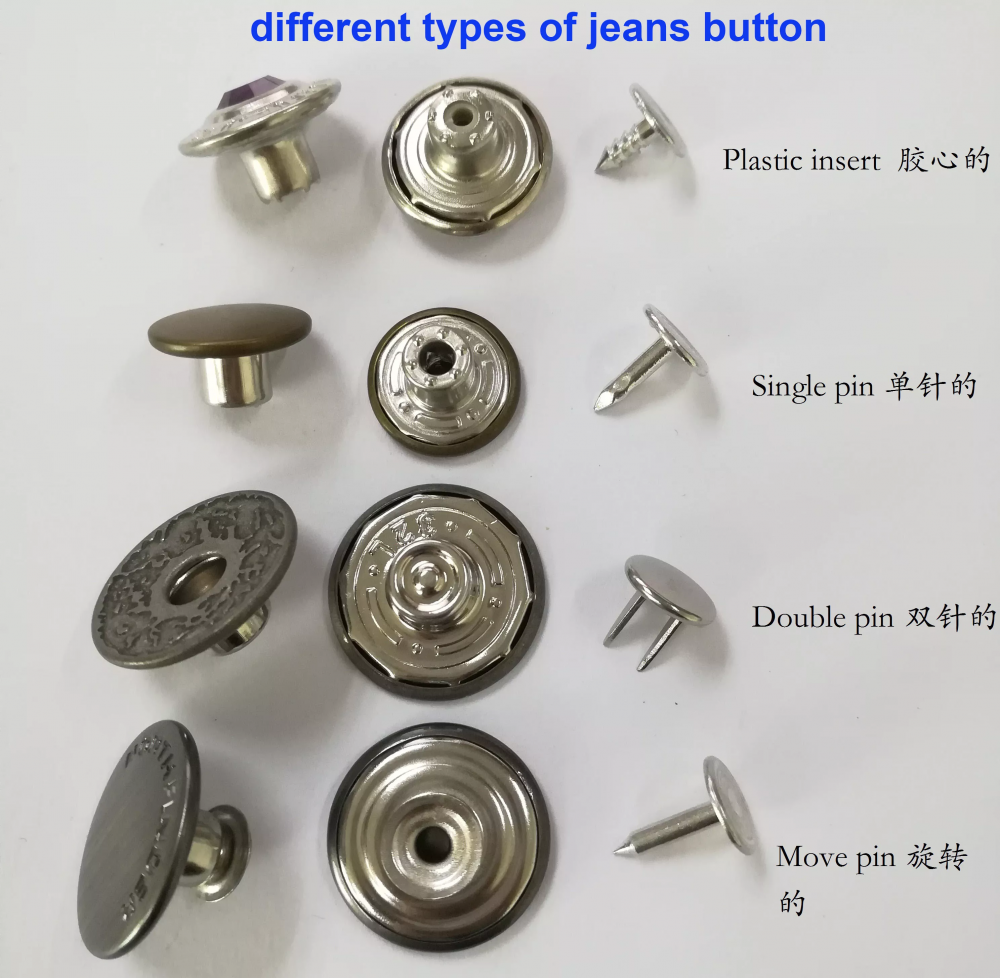

Metal buttons are made of metal materials. The styles of metal buttons can be divided into metal snap buttons, high-end snap buttons, jean buttons, denim buttons, rivets, eyelets, sewing buttons and so on. The design of metal buttons is different from pure art designs such as carving, sculpture, and painting. It includes shape, pattern, color, material, practicality, durability, mass industrial production and processability. Metal buttons can be divided into: metal jeans buttons, snap buttons (spring snap button, press snap button, prong ring snap button, pearl snap buttons), eyelet, rivet, tipping, two or four hole buttons, sewing butons, shank buttons etc. The design of metal buttons is different from pure art designs such as carving, sculpture, and painting. It includes shape, pattern, color, material, practicality, durability, mass industrial production and processability.

Geometric shape and three-dimensional shape of the appearance.

Partial modeling. Due to factors such as manufacturability, processability, and safety, the most common shapes of metal buttons are round, hexagonal, unequal, and equilateral. The most common three-dimensional shapes are spherical, hemispherical, embossed, and other three-dimensional shapes. The most common partial modeling is to model individual or all partial details on the basis of the external shape, such as adding Arabic numerals, English letters, plane composition, patterns, animals, portraits, flowers, registered trademarks, and patterns, etc.

Manufacturing process editor

Metal button/hardware button manufacturing process: size mold opening (mold repair)--》button surface mold (shape)/flower mold (LOGO) pattern, etc.)--》trial mold, sample--》roughing--》oil washing/polishing--》electroplating,--》other process treatment (oiling/laser/silk screen, etc.)--》inspection/testing--》packaging and delivery.

Alloy button manufacturing process: design drawing--》copper engraving--》electrical discharge machining--》bulk mold--》trial mold--》roughing--》polishing/hand polishing--》electroplating--》other process treatment (oiling/laser/silk screen, etc.)--》inspection/testing》packaging and delivery.

Button inspection methods and requirements & standards:

1. Check the sample or confirm the sample. Check whether the color and model are consistent with the sample;

2. The button surface should not have cracks, gaps, unevenness and obvious scratches;

3. There should be no cracks or bubbles on the front and back; no rotten edges, uneven thickness;

4. The pattern should not have obvious deformation, no white eyes, white circles, etc.;

5. The buttonholes should be smooth and unobstructed; the needle holes should not be pierced or broken, and should be symmetrical and without large eyes. If it is a dark eye button, the dark eye groove should be smooth and without obvious cracks.

6. After electroplating or other process treatment, the effect should be uniform. If some special effects cannot be consistent, they can be packaged separately. 7. The color difference of buttons in the same batch should not be lower than the fourth level standard of GB250 compared with the samples, and should not be lower than the third level standard of GB250.

8. Packaging inspection, after the appearance inspection/customer required performance test are all qualified, then repackaging. The certificate of conformity or other labels should be placed during packaging. The quantity of packaging should be consistent with the regulations, and the actual quantity of each bag must be consistent with the specified quantity. If it is found that the tolerance is exceeded due to different thickness or other reasons, all of them must be inspected.

If would like to know more buttons details, contact Sandy Lee Whatsapp number: +86 15013504458

Email address: sandylee@difeibutton.com